YY-900N Automatic Shoulder/Neck Box Assembly Machine is a model developed and manufactured independently by Yuanyi to automate rigid box making process fully. It can work with all of the shoulder rigid boxes on the market. It sprays glue on the wall of the base box and then inserts or fits the neck into the base box and is glued to secure it. This machine drastically increases the precision and working speed for the box manufacturers, highly recommended for shoulder neck rigid box projects.

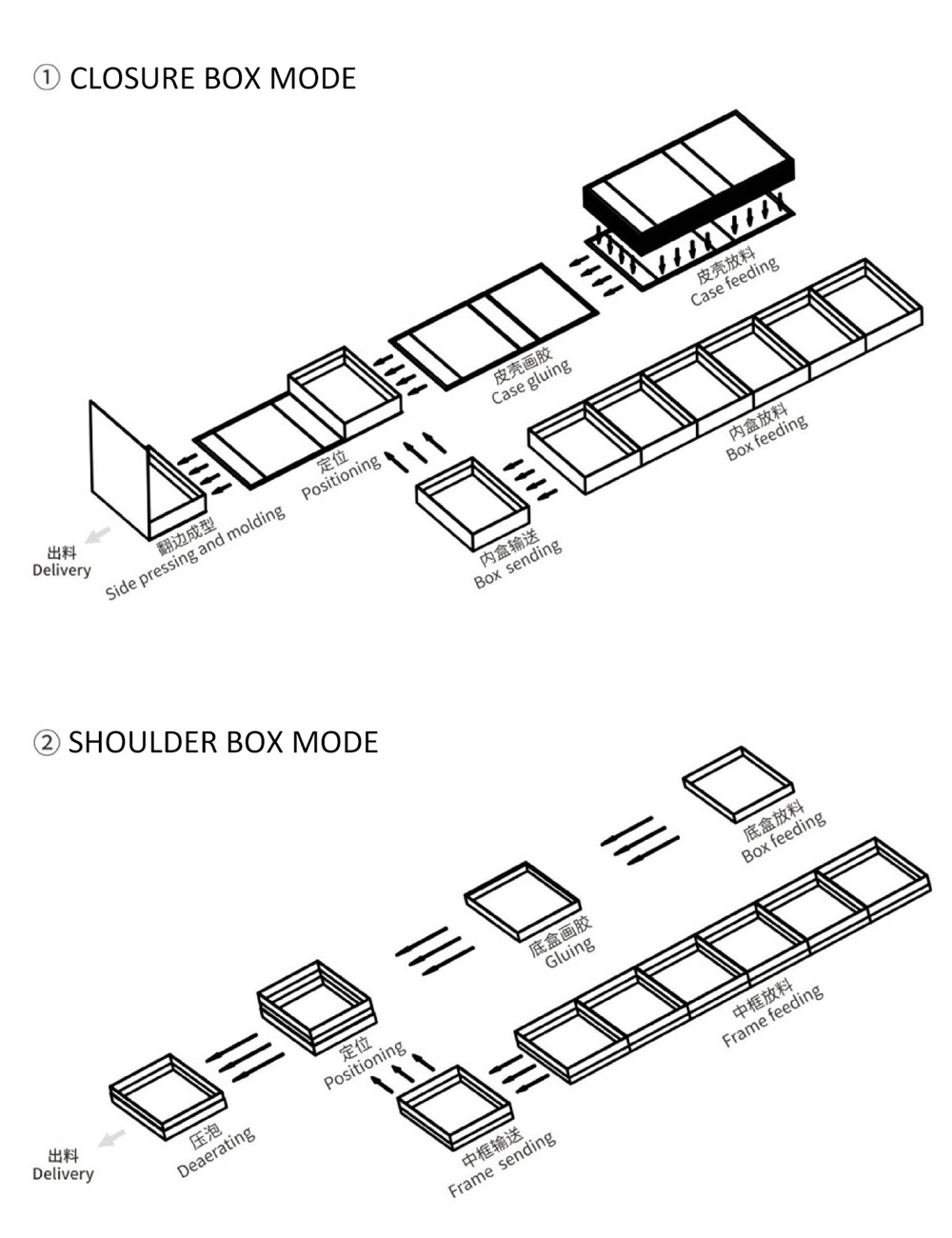

Working Flow

Main Technical Parameters |

Max box size | 420mm×420mm×115mm |

Min box size | 85mm×85mm×35mm |

Speed | 18-30 pcs/min |

Positioning accuracy | ≤ ± 0.1mm |

Machine size | 4940×2000×2000mm |

Machine weight | 800kg |

Machine power | 8KW/AC220V |

Air pressure | 8Kpa |

Number of glue nozzles | Standard 1. custom 2. |

Main Configuration

1. Japanese Panasonic PLC, frequency converter, temperature controller.

2. Japanese Panasonic photoelectric sensor.

3. Japanese Panasonic servo motor.

4. Japanese Panasonic servo drive.

5. Japanese Panasonic negative pressure switch.

6. Schneider Electric SA proximity switch sensor.

7. XWB DC motor.

8. Taiwan Meanwell power.

9. Jingtai hot melt glue box.

10. Pneumatic vacuum electronic components-Taiwan AIRTAC, XINGCHEN, AIRBEST.

Main Features

1.High safety, short setting and adjusting time, fully digital, manual debugging is not needed, which is convenient and fast.

2. Easy to operate, anyone can easily learn to use it well.

3. Fast processing speed, spraying in lines, which is glue saving, strong bonding. No leakage.

4.Automatic glue dispensing, diversified and simplified.

5. The bubble pressing process after the box glued to the rigid cover is precise and stable.

6. The servo motor and automatic control system used in each part are imported high-end accessories with high stability, high accuracy and long service life.