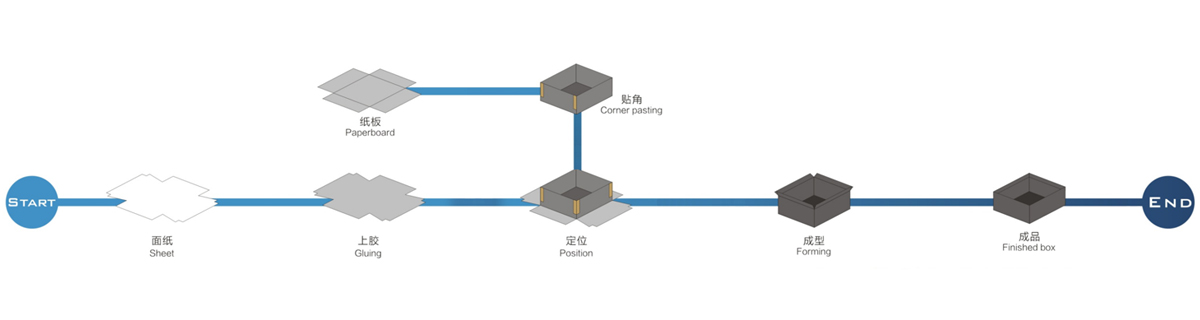

HX Fully Automatic Rigid Box Production Line is a combination of 3 machines, a corner pasting machine, a CCD positioning machine (with gluing and positioning, bubble pressing units) and a rigid box forming machine. Firstly the gluing machine feeds the glued paper to the conveyor belt, meanwhile on the side the corner pasting machine pastes the grey board boxes and feeds the boxes to the conveyor belt where the positioning machine grabs these boxes and lays on the glue paper. Followed by a bubble pressing process, and finally the products are delivered to the box forming machine to complete the last process.

Working Flow

Main Technical Parameters

HX-8042A includes two parts, the automatic visual positioning module and book cover feeding module, including the functions of automatic paper feeding, gluing, positioning. Widely used in the production of various rigid setup boxes and book covers.

HX-8042A |

Model Name | Automatic Box Positioning Line |

Max box size | 420*410*120MM |

Min box size | 80*50*10MM |

Conveyor Belt | Width 620mm Length 5.8 Meter |

Robot Arm | YAMAHA |

Working Speed | 0-30 PCS/Min |

Power supply | 380V |

Machine Weight | 2000kg |

Machine Dimension | L7000*W4000*H2200mm |

HX-4050 adopts PLC programmable control, servo motor drive, user-friendly interface with touch screen, automatic paper feeder, tape feeding motor. This module has stable performance, high precision and durability. It's easy to operate with high efficiency. A good helper for rigid box manufacturers.

HX-4050 |

Model | Automatic Corner Pasting Machine |

Max box size | 450*450*130MM |

Min box size | 50*50*10MM |

Feeder Unit for positioning line | 1 set |

Working Speed | 0-40 PCS/Min |

Power supply | 220V/1.5KW |

Machine Weight | 800kg |

Machine Dimension | L2000*W1050*H1550mm |

HX-400A is a rigid box forming module. It uses the box holding manipulator to put the positioned box uoder the mould which could automatically suck the box, wrap the edge, press the bubble and completes the entire box forming process at one time. It greatly improves the working efficiency and quality of products.

HX-400A |

Model | Automatic Box Forming Machine |

Max box size | 400*400*110MM |

Min box size | 50*50*10MM |

Air Pressure | 0.4-0.6MPA |

Working Speed | 0-30 PCS/Min |

Power supply | 220V |

Machine Weight | 850kg |

Machine Dimension | L1200*W1600*H2150mm |

Main features

1. This machine adopts PLC control system, touch screen interface and camera positioning system, which is accurate in positioning;

2. The system is simple to use and easy to adjust, quick to change product.

3. Automatic paper feeder,simple operation, avoids catching double or even multiple sheets;

4. HD camera, no need for moving camera;

5. The machine has its own malfunction diagnosis function, it shows the operator where the issue is.