XHS-2 CCD Auxiliary Positioning Machine Module is often used in automatic rigid box and rigid cover making process, and directly added to any type of semi-automatic box/rigid cover gluing machine with conveyor belt. Its double robot arms make the positioning much more efficient and its multi-functionality offers broad flexibility to the customers. Use it smart, it will surprise you.

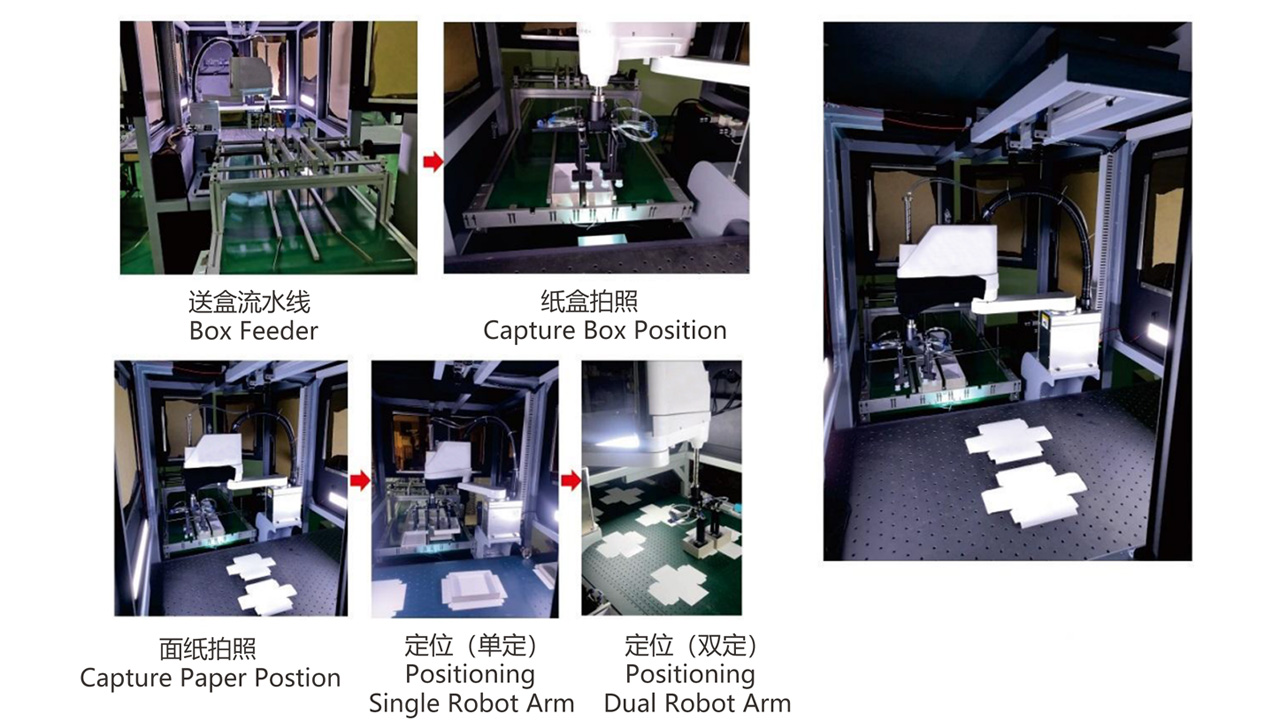

Working Flow

Main Technical Parameters |

Max box size | L450*W220*H120 mm |

Min box size | L50*W50*H10 mm |

Max rigid cover size | L500*W320*H6 mm |

Min rigid cover size | L50*W50*H1 mm |

Working speed | ≥40Pcs/min |

Precision | ±0.2mm |

Machine size | 1800×1200×1850mm |

Machine weight | 500kg |

Machine power | AC220V/2.5KW |

Air pressure | 6-8 Pa |

Main features

1. Multiple functions: This CCD visual positioning system can be used to perform rigid box positioning, rigid cover positioning and some irregular kinds of rigid box positioning.

2. Short adjusting time: (1) With four cameras, this machine can capture the paper position as well as the box position, which greatly reduces the debugging time. (2) By using a large angle of visual positioning, the camera does not move when changing, avoiding extra camera calibration procedure, which greatly reduces time for adjusting the machine to make new products.

3. Less after-sales work, instead of the PLC control unit, we adopt the special control unit of manipulators which we independently developed, greatly improving the stability of the equipment. Whether it is a manipulator, camera or control unit that doesn’t work, we only replace it instead of repairing it, which reduces the waste of time for customers.

4. Highly cost effective, can be added to any semi-automatic box making line that has a feeder gluing machine and a conveyor belt, very budget-friendly for any factory owner who is looking to upgrade their semi-automatic box/rigid cover production line to fully automatic.

Main configuration

1. Four high-speed industrial-grade cameras, ultra-high-precision, large vision.

2. SCARA 600 manipulator, Japanese Nidec-Shimpo reducer, Japanese Tamagawa servo motor, PMI screw spline shaft.

3. Independently developed intelligent industrial robot core controller.