SPECIFICATION

HX rigid box forming machines are semi automatic models designed for rigid box making process. It's often set up side by side with a gluing machine and box positioning machine, a great investment for rigid box manufacturers. These 3 models all have an automatic job setting function, it takes only 2 mins to set up your jobs on the user-friendly touch screen.

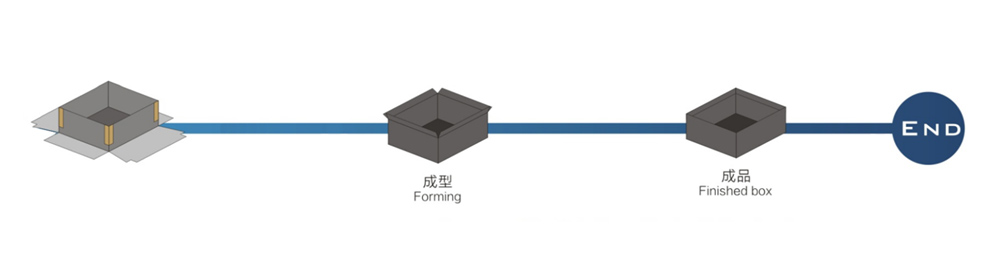

Working Flow

|

Main Technical Parameters

|

|

Machine Model

|

HX-5242

|

HX-6050

|

HX-6050A

|

|

Max box size

|

500*400*120 mm

|

600*500*110 mm

|

600*500*150 mm

|

|

Min box size

|

70*50*10 mm

|

70*50*10 mm

|

120*80*10 mm

|

|

Working speed

|

0-20 pcs/min

|

0-20 pcs/min

|

0-20 pcs/min

|

|

Paper fold in size

|

10-60mm

|

10-60mm

|

10-60mm

|

|

Machine size

|

1200*1300*2200mm

|

1200*1300*2200mm

|

1300*1400*2700mm

|

|

Machine weight

|

700KG

|

750KG

|

800KG

|

|

Machine power

|

AC220V/3KW

|

AC220V/3KW

|

AC220V/3KW

|

|

Air pressure

|

0.5-0.8 Pa

|

0.5-0.8 Pa

|

0.5-0.8 Pa

|

Main features

1. Automatic job setting, PLC control, touch screen user-friendly interface for parameter setting and error display.

2. Pneumatic plus PLC control system, once operators input the size of the box and the mold, the machine can automatically adjust and the data will be stored in the computer for the next project with the same box.

3. All processes are completed in one action, speeding up box production.

4. This machine model is easy to set jobs and stable, simple to operate, easy to use, has good bubble pressing effect, it can be applied to work on paper box, wooden box, or leather box, needless to press bubbles after.