SPECIFICATION

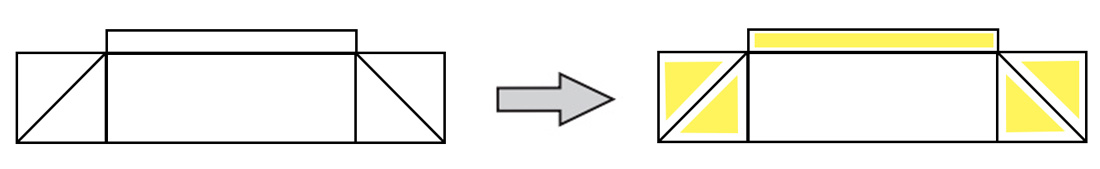

YY-600SF Adhesive Tape Pasting Machine uses an air suction conveyor belt to transport the wings of the collapsible box, the wings are positioned by optical fiber and the the adhesive tape pasting part will paste the linear tape first, followed by the second pasting part which will paste the triangle or square adhesive tapes. And finally, it is rolled flat for bubble pressing.

This machine can be used to paste double faced adhesive tapes on many products, including posters, envelopes, rigid boxes, carton boxes and other types of paper boxes.

Working Flow

Main Technical Parameters |

Max wing size | L800mm×W200mm |

Min wing size | L100mm×W35mm |

Max tape size | L200mm×W200mm |

Min tape size | L20mm×W20mm |

Conveyor speed | 12-24m/min |

Working speed | 40-70Pcs/min |

Positioning accuracy | ≤ ± 0.1mm |

Machine size | 2200×900×1600mm |

Machine weight | 400kg |

Main Features

1. Two or four triangular double-sided adhesive tapes and one linear double-sided adhesive tape can be applied simultaneously.

2. Fiber induction and servo positioning, accurate double-sided adhesive tape positioning.

3. The conveyor belt sucks air throughout the whole process, hence the product is transported smoothly with minimum error.

4. Smart screen interface, you can set the parameters and length of the linear double-sided adhesive tape on the touch screen.

5. Manual feeding, simple control and high production efficiency.

6. Modularized design, this machine can be connected to the robotic arm automatic feeding.